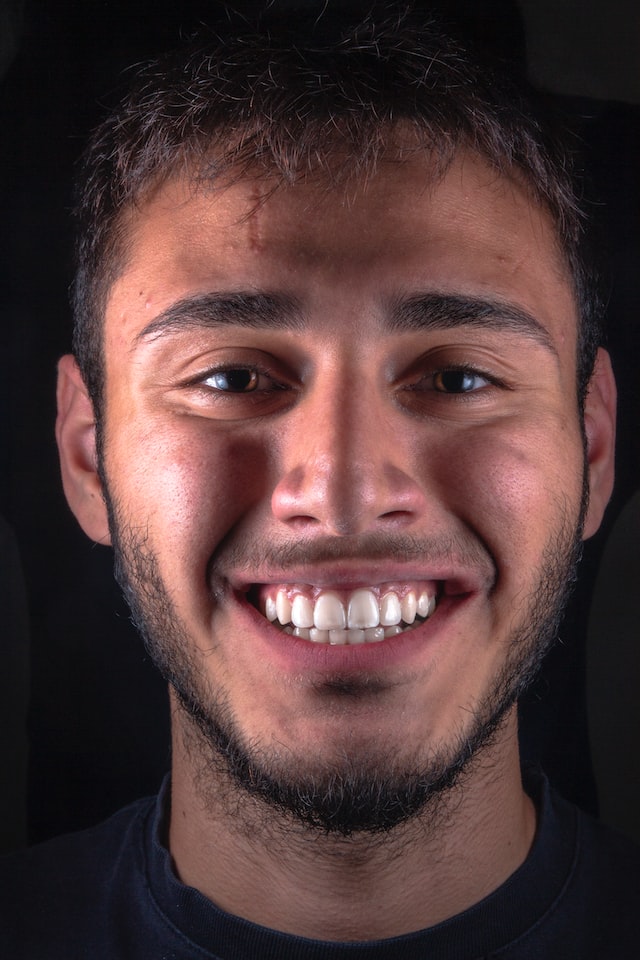

Dental implants have become the most frequently recommended choice to replace missing teeth today. Published studies confirm that when dental implant treatment is performed correctly, 10-year implant survival and success rates can be ranging from 34.9% to 100% 1-4.

Know more about DiDi

Dental implants have become the most frequently recommended choice to replace missing teeth today. Published studies confirm that when dental implant treatment is performed correctly, 10-year implant survival and success rates can be ranging from 34.9% to 100% 1-4.

Clinical examination is very vital to the range of the big variation in the success rate. Despite the latest development, towards an ultimately digital dental implant therapy workflow with the use of robotic assistance. But still until this date, during the first visit [clinical examination] a simple ruler or a caliper is used to determine the spaces available for implant placement.

Since 1982 [Toronto Osseointegration Conference springboard dental implantology out of an era of unpredictable and often short-lived treatment outcomes based upon limited research, to one that is evidence-based and predictable] that has not been updated with a technology to enhance the experience between the doctors and patient.

When it comes to diagnosis visit the clinician uses a ruler or a caliper to evaluate the potential implant sites for interdental and interocclusal space. This device enables quick and accurate decision making with accuracy of 0.1 mm.

Due to inherent inaccuracies in measuring intraorally with a device [ruler] with 1mm lines an impression [a mold] is made to measure them extra orally. The impression is poured in stone with an average 4 hours setting time and only then its ready for evaluation. However, this item due to its premeasured required dimensions can enable the doctor to immediately decide, yes or no, while the patient is in the dental chair.

This product [DiDi] will eliminate an extra patient’s visit to evaluate the diagnosis casts once poured and available dimensions calculated. The patients waiting to pour and inform the possibility to receive a single or multiple implants or the referring the patient to an orthodontist or other specialty to create the space needed to be able to receive an implant is eliminated and 2nd visit to finalize the plan can be finalized in the 1st visit itself.

It is disposable, hence hygienic during the covid Era, it’s Pure plastic; hence recyclable and it is transparent to visualize the soft tissue and bone under it while working. Today, prefabricated metallic instruments are used to determine edentulous spaces and drilling is done through which could create patient discomfort from the metal banging in the mouth, this is light weight [3 gram] and completely avoids any accidents if falls from the doctor’s hand.

It minimizes the first visit [intraoral clinical examination] chair time from 15-20 minutes to 1-5.

During Surgery

It is important to ensure there is enough tridimensional space to house the desired implant diameter structures in close proximity [e.g., a minimum safety distance of at least 1.5 mm is suggested to minimize bone resorption and

reduction or loss of the interproximal papilla] to the neighboring tooth in surgical procedure. It is almost impossible to have that distance with a ruler or a caliper to guide your drill to achieve such accuracy.

Interocclusal Space

The height space must also be measured to determine whether there is enough space to place the restoration. If several implants must be placed adjacent to each other, an inter-implant distance of at least 3 mm should also be considered to minimize crestal bone loss and inter-implant papilla loss 5-9. It reduces Stress level of the Surgeon during the procedures. Both the patient and the clinician may avoid the additional appointments that are necessary for subsequent measurement confirmation and any other modifications needed in case of miscalculation. With device in hand all these measurements are readily calculatable any time inside patient’s mouth.

Material Used

Makrolon® is polycarbonate thermoplastic resin, lightweight, heat resistant with glass-like transparency, and is impact resistant – even at low temperatures. It also has high dimensional stability and is easily molded yet displays excellent heat resistance with a glass transition temperature of up to 148ºC [autoclavable at 121ºC for 20 minutes]

Advantage

- 1. Precise placement of implants next to each other.

- 2. Immediate decision-making with accuracy during diagnosis visit

- 3. Its three-dimensional shape allows precise evaluation of anatomic points such as the size of the edentulous space in both jaws even if saliva is obscuring clarity in the posterior area

- 4. Precise analysis of interocclusal space topography while closing the mouth

- 5. Provides information about size, direction, and teeth location for accurate positioning of implants

- 6. Accuracy of 0.1 mm intraoral visibility is not possible with a caliper

- 7. Reduced surgical exposure time

- 8. Less invasive, flapless surgery, and, therefore, less chance of swelling

- 9. Clinician’s state of low stress even with minimal skills

- 10. Transparency of material which allows seeing through the model while drilling

- 11. Eliminates stereolithography fabrication process

- 12. Does not require an extra mouth opening that jeopardizes surgical procedure like other surgical guides.

- 13. cost-effectiveness

- 14. Added value to the product is that it comes with a software that can have both, digital format in the CBCT and analog format in the mouth simultaneously. Which is a benefit that means if a patient that had CBCT done in another country and decides treatment elsewhere for surgery might not have to go for another X-RAY. Which means save time and money. This is the only device that has a prefabricated analog & digital format 1:1 ratio in any CBCT to its same dimension in a software.